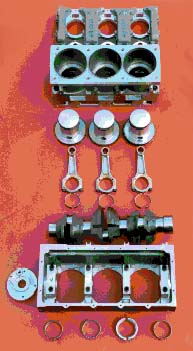

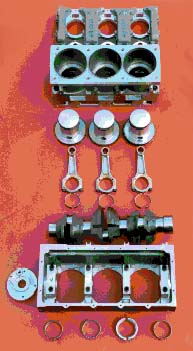

A feasibility project to design and build the first modern three cylinder stepped piston engine was assisted by a British Government DTI Smart award for innovation. The components for this research engine can be seen in the photo above, with the inherent simplicity and low parts count immediately apparent.

Based on the extensive experience and knowledge at BHE an important stride forward is now feasible for future low emission vehicle and industrial engine requirements. The three cylinder engine shown above formed the basis of a low emission, low cost hybrid electric vehicle powertrain study. Predictive analysis showed very low specific fuel consumption levels. The ability to operate with variable compression ratio using far simpler methods than those required for four stroke engines means that further advances are within reach with this unique pump charged two stroke engine design.

w.jpg)

Most of the engines built to date are spark ignition units. The SPV580 engine (see Unmanned Aircraft Engine page) has achieved a high specific power and power to mass ratio. Operating at the modest speed of only 5250 RPM this engine produces up to 61kW per litre. Our most recent papers "An experimental and analytical investigation of a multi-fuel stepped piston engine" (Journal of Applied Thermal Engineering April 2012), "Advanced modern low emission two-stroke cycle engines" (Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. Vol. 225 No.11, November 2011), "Stepped Piston Engines for Multi-Fuel UAV Application" (IMechE Conference on Propulsion Systems for Unmanned Aircraft, Bristol, 14 April 2005), "A Stepped Piston Engine for UAV Application" (UVS TECH 2001 Conference, Brussels, November 2001) and "Initial Development of a Multi-fuel Stepped Piston Engine for Unmanned Aircraft Application" presented at the Istituto Motori ICE99 Conference in Capri 12-16 September 1999, by Dr Peter Hooper BEng, CEng, FIMechE, provide more detail on this engine.

The SPV1000 engine is a V4 cylinder 55kW engine originally designed for automotive use but also for industrial application weighing only 42kg. Based on an earlier SPV-4 research engine that produced 55.2kW (74BHP) at 5250 RPM, with a torque variation of only 7.8% in the 2000 - 5000 RPM range. Maximum torque being 97.6Nm at 3500 RPM, and a minimum SFC so far of 270g/kWh (without direct injection).

© BERNARD HOOPER ENGINEERING LTD