ADVANTAGES

WET SUMP - conventional 4 stroke lubrication

PLAIN BEARINGS

NO VALVE GEAR

LOW THERMAL LOADING OF PISTON

LOW EMISSIONS WITH DURABILITY

LOW MANUFACTURING COSTS

COMPACT LOW MASS DESIGN

EXTENDED OIL CHANGE PERIODS (Oil does not degrade)

FAST WARM UP (lower cold start emissions)

ABILITY TO OPERATE ON A WIDE RANGE OF FUELS (including GAS)

Piston mass is naturally higher for a stepped piston design. However our unique approach means that for identical power cylinder bores the stepped piston is only around 20% heavier than a conventional looped scavenged two stroke piston. The multi section or step of the piston provides a flange stiffening effect resulting in thinner skirt sections. If necessary the mass increase can be reduced to below 15% by composite methods. However the engine uses the two stroke cycle and therefore with the absence of load reversals piston mass is not as critical as it is for four stroke engines. The Hooper stepped piston also provides improved load bearing and guidance resulting in low ring wear and reduced piston noise.

LUBRICATION

Lubrication is a key area where the stepped piston engine differs from conventional two-stroke engines. In conventional two-stroke engines oil is metered by a precision metering pump or lubrication can be achieved by mixing oil in the liquid fuel supply. Both of these methods are completely avoided using a stepped piston engine. In a stepped piston arrangement the fuel is neat and the oil is contained within the sump. Crankshaft drill ways provide oil supply to all the bearings, as is common practice in four-stroke engines. The piston and rings are also lubricated in similar methods to four-stroke engine practice (even the upper power piston rings). Essentially no oil is required in the fuel of a stepped piston engine and the corresponding oil consumption achieved is significantly lower than can be achieved by a conventional two-stroke engine.

BEARINGS

Due to the fact that a four-stroke type of lubrication system can be used with a stepped piston engine, this enables use of a pressure fed system to all bearings and therefore the use of well proven hydrodynamic plain shell bearings. Conventional crankcase scavenged two-stroke engines generally require the use of rolling element bearings. These are a source of noise and significantly more expensive than plain shell bearings.

COOLING STRATEGY

Piston cooling is a particular challenge for conventional two-stroke cycle engines. However the stepped piston is cooled in two positive ways that are impossible with a conventional engine. The sump lubrication system enables oil cooling of the underside surfaces of the stepped piston (as is common in four-stroke engines). In addition to this, the upper surfaces are cooled by the incoming air charge. The improved cooling of the piston significantly improves durability when operating on the two-stroke cycle and particularly when direct injection is applied, thereby offering very low emissions operation with high durability.

COST OF MANUFACTURE

The reduced parts count when compared with an equivalent four-stroke engine readily offers a reduced engine unit cost. Independent cost studies have shown significant cost savings compared to conventional engines. For an automotive inline 3 cylinder engine, these equated to a 22% unit cost saving and a 40% reduction in investment costs.

At Norton Villiers cost studies for a twin cylinder stepped piston engine (Norton Wulf engine) against a comparable twin cylinder crankcase scavenged two-stroke engine revealed a 25% unit cost reduction. The piston is marginally more expensive but this is more than offset by the costs of the rolling element bearings and the precision metering oil pump that is essential for the crankcase scavenged engine. The stepped piston engine, in contrast, can employ a low cost gerotor type automotive oil pump, as are typically applied to four-stroke engines.

Even a single cylinder stepped piston engine offers cost savings. When compared to a side valve four-stroke industrial engine, the fully die-castable stepped piston engine was found to be 10% cheaper in terms of unit cost. Of course if an overhead valve four-stroke engine is considered, the savings would be increased above 10%.

ENGINE SIZE

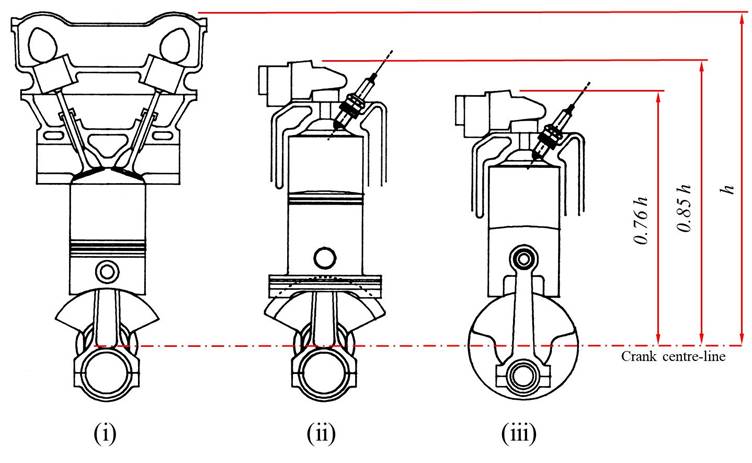

In the diagram below a comparison is drawn between the overhead cam four-stroke engine, the stepped piston direct injection engine and a conventional crankcase scavenged two-stroke engine with direct injection. All of the engines shown have identical swept volumes.

Engine height comparison of: (i) OHC four-stroke, (ii) stepped piston, and (iii)

crankcase scavenge two-stroke engines of identical swept volumes.

As can be seen, the physical size of the stepped piston engine (ii) lies between the four-stroke (i) and two-stroke engines (iii). The identical swept volume is essential to allow a fair comparison to be made. It should however be noted that for the same operational engine speed the four-stroke engine would have to be larger than that shown in order to achieve the same power output. In terms of performance and mass the stepped piston engine is closer to the conventional two-stroke engine.

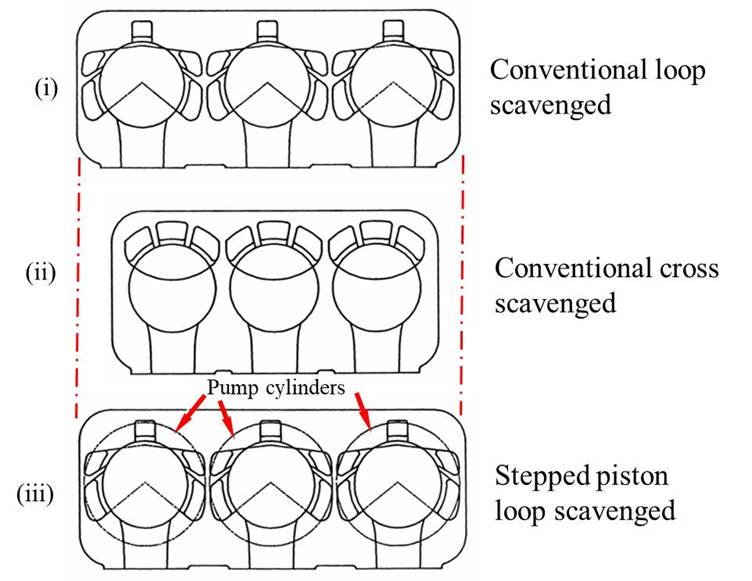

In the diagram below a comparison of port plan layouts is shown with identical bore:stroke ratios for fundamental two-stroke engine layouts. The diagram compares conventional two-stroke crankcase scavenged engines of loop scavenged (i) and cross scavenged (ii) types with a stepped piston loop scavenged (iii) engine.

Two-stroke engine port layout

comparison of: (i) Schnurle

loop scavenge, (ii) Cross scavenge, and (iii) stepped piston segregated loop

scavenge engines of identical bore diameter and swept volumes.

With the identical swept volume and bore:stroke ratio constraints, it can be clearly seen that the cross scavenged engine port arrangement (ii) allows the most compact engine arrangement allowing a minimum bore centre distance. Cross scavenging arrangements have historically proven to be successful in two-stroke marine outboard engines. However the scavenging efficiency is lower than the comparable efficiencies achievable using loop or indeed uni-flow scavenging. For this reason stepped piston engines prototyped to date have mostly used loop scavenging layouts rather than cross scavenging. The lower image clearly shows the pump cylinder bore of the stepped piston. Contrary to what may be a natural assumption for a stepped piston engine design, the cylinder centre distance is not increased when compared with an equivalent conventional loop scavenged two-stroke engine and this is clearly shown in the above comparison. The reason for the identical size lies within the fact that the profile of the pumping cylinder adds no additional bulk to the necessary footprint required for the port passageways needed for the conventional loop scavenged two-stroke engine.

LONGER LIFE OF LUBRICANT

As stated elsewhere on this website and in published papers, the stepped piston engine has regularly demonstrated significantly lower oil consumption than can be achieved with conventional engines. In addition to the lower oil consumption, oil from test engines has also been analysed by independent specialist Laboratories for viscosity and contaminants. After long term dynamometer (in excess of 1000 hours) and full load endurance testing (in excess of 200 hours) the engine oil has been repeatedly found to still be within the specification of the new oil sample. This means that whilst oil replacement will still be required, it should be possible to extend the life of the lubricant between the necessary replacement intervals.

FUEL TOLERANCE

To date the stepped piston engine has been successfully operated on conventional fuels such as gasoline and diesel. Good results have been experienced with gaseous fuels such as natural gas and hydrogen. Indeed recent work has indicated that the engine is very well suited to hydrogen fuelling and the wide ranging challenges that hydrogen operation presents. A key advantage of the stepped piston engine's design philosophy is that the engine is able of operate on neat fuel without any need to add oil to the fuel (unlike conventional two-stroke engines).

Designed and developed under MoD contract, this 580 cm3 four cylinder engine produces 35.4kW (47.5BHP) at 5250 RPM. The V4 configuration offers exceptional smoothness with low noise , vibration and harshness (NVH) characteristics similar to a V8 four stroke engine. Gasoline and kerosene AVTUR / JET A-1 versions have been developed. The 30kW target performance was achieved with simple exhaust system and a very low engine mass of 18.2kg (air-cooled) or 18.5kg (liquid-cooled).

For further information on the stepped piston engine (sometimes also known as the stepped engine or step piston engine) or contract design and development of conventional 2 and 4 stroke engines and test rigs, see linked pages or contact BHE:-

© BERNARD HOOPER ENGINEERING LTD